- 01 Investment Opportunities

- 02 States

- 03 Textile Parks

- 04 Textile Institutes & R.A

- 05Trade Fare & Events

- 06Trade Fare Associations

- 07 About Us

- Sectors

- Technologies

- Services/Utilities

- NAGALAND

- CHATTISGARH

- BIHAR

- ASSAM

- WEST BENGAL

- UTTARAKHAND

- UTTAR PRADESH

- TRIPURA

- TELANGANA

- TAMIL NADU

- SIKKIM

- ARUNACHAL PRADESH

- RAJASTHAN

- PUNJAB

- Orissa

- DELHI

- MIZORAM

- MEGHALAYA

- MANIPUR

- MAHARASHTRA

- MADHYA PRADESH

- ANDHRA PRADESH

- KERALA

- KARNATAKA

- JHARKHAND

- JAMMU & KASHMIR

- HIMACHAL PRADESH

- HARYANA

- GUJARAT

- GOA

- Indian Institute of Technology

- M.S. University of Baroda

- National Institute of Fashion Technology Raebareli

- National Institute of Fashion Technology Shillong

- National Institute of Fashion Technology Srinagar

- Ahmedabad Textile Industry's Research Association (Atira)

- Bombay Textile Research Association

- South India Textile Research Association

- Northern India Textile Research Association

- Synthetic & Art Silk Mill's Research Association

- Man-Made Textile Research Association

- Indian Jute Industrie's Research Association (IJIRA)

- Bapuji Institute of Engineering & Technology

- Wool Research Association

- National Institue Of Event Management

- SGGS College of Enginnering & Technology

- Manikyalal Verma Textile Institute

- Sarvajanik College of Engineering & Technology

- Department of Applied Chemistry & Technology

- Indian Institute of Carpet Technology

- Kumarguru college of Technology

- SSM College Of Engineering

- Institute of Jute Technology

- Veermata Jijabai Technological Institute

- Dr. B.R. Ambedkar Engg. College

- GZS Campus College of Engineering & Technology

- Shri Vaishnav Institute of Technology & Science

- Anuradha Engineering College

- Jawaharlal Darda Institute of Technology

- Lalbhai Dalpatbhai College of Engineering

- Institute of Textile Technology

- Government College of Engineering & Textile Technology

- Government College Of Engineering And Textile Technology

- University College Of Engineering Osmania University

- Uttar Pradesh Textile Technology Institute

- Government Sri Krishnarajendra Silver Jubilee Technological Institute

- RTE Society's Rural Engineering College

- S.L.N College of Engineering

- Bannari Amman Institute of Technology

- Jaya Engineering College

- K. S. Rangasamy College of Technology

- RVS College of Engineering & Technology

- DR. BABASAHEB BHIMRAO AMBEDKAR GOVERNMENT POLYTECHNIC

- Govt. Institute of Textile Chemistry & Knitting Technology

- Punjab Institute Of Textile Technology

- Technological Institute of Textile and Sciences

- Baba Hira Singh Bhattal Institute of Engineering and Technology

- Government Polytechnic

- Govt. Polytechnic

- Government Polytechnic Farrukhabad

- DR.B.R.A. POLYTECHNIC COLLEGE

- Shri Vaishnav Polytechnic College

- Government Polytechnic College

- Assam Textile Institute

- Govt. Polytechnic, Barari

- R.C. Technical Institute

- A.C. College of Technology, Anna university

- Sir Bhavsinhji Polytechnic Institute

- Dr. S and S.S. Gandhi College of Engg. and Technology

- Mantra Institute of Textiles

- Govt. Polytechnic, Sadar

- Govt. Polytechnic College

- SASMIRA’S INSTITUTE OF MAN-MADE TEXTILES

- Govt. Institute of Textile technology

- Government Institute of Textile Technology

- S.R. Vastrad Rural Polytechnic Institute, Guledgudd

- R.T.E.Societys Rural Polytechnic

- PSG College of Technology

- Govt. Institute of Textile Technology.

- Bapuji Polytechnic, Shabanur

- H.K.E. Polytechnic

- Central Polytechnic, Vattiyoorkavu

- Govt. Polytechnic, Kannur

- Institute of Textile technology, Taramani

- Annamalai Polytechnic, Chettinad

- Erode Institute of Technology

- G.R.G Polytechnic for Women

- Nachimuthu Polytechnic College

- Shri Krishnarajendra Silver Jubilee Technological Institute

- P.S.G. Polytechnic

- Rukmini Shanmugam Polytechnic

- SSM Polytechnic College

- Thiagarajar Polytechnic

- The Karur Polytechnic

- V.L.B. Janaki Ammal Polytechnic

- Erode Institute of Chemical Technology

- Gomathi Ammal Polytechnic

- K.L. Nagaswamy Memorial polytechnic

- Latha madhavan Polytechnic

- University Department of Chemical Technology

- Murugesan Institute of Technology, Karmapuram

- Nanjappa Institute of Technology, Karumathampatti

- Pasumpon Netaji Polytechnic

- Rudraveni Muthuswamy Polytechnic, Palampampathy

- Senthur Polytechnic College

- Sri Sowdambika Polytechnic

- Subramaniam Polytechnic

- National Institute of Fashion Technology Bangaluru

- National Institute of Fashion Technology Bhopal

- National Institute of Fashion Technology Bhubaneswar

- DKTE Society's Textile & Engineering Institute

- National Institute of Fashion Technology Chennai

- National Institute of Fashion Technology Delhi

- National Institute of Fashion Technology Gandhinagar

- National Institute of Fashion Technology Hyderabad

- National Institute of Fashion Technology Jodhpur

- National Institute of Fashion Technology Kangra

- National Institute of Fashion Technology Kannur

- National Institute of Fashion Technology

- National Institute of Fashion Technology Mumbai

- National Institute of Fashion Technology Bihar

- Federation of Indian Chambers of Commerce & Industry (FICCI)

- Indian Technical Textile Association (ITTA)

- Confederation of Indian Textile Industry (CITI)

- Apparel Export Promotion Council

- The Cotton Textiles Export Promotion Council

- The Synthetic & Rayon Textiles Export Promotion Council

- Wool and Woollens Export Promotion Council

- Wool Industry Export Promotion Council

- Indian Silk Export Promotion Council

- Carpet Export Promotion Council

- Export Promotion Council for Handicrafts

- Powerloom Development & Export Promotion Council

- Handloom Export Promotion Council

- Jute Products Development and Export Promotion Council

- Sports Goods Export Promotion Council

- Council for Leather Exports

- Knitwear & Apparel Manufacturers Association of Ludhiana

- Tiruppur Exporters' Association

- The Southern India Mills Association

- Garment Exporters & Manufacturers Association

- Gujrat Exporters & Manufacturers Association

- Clothing manufacturer association of india

- Eastern India Garment Manufacturers & Exporters Federation

- Chamber of textile trade & industry

- Central Silk Board

- The Synthetic & Art Silk Mills' Research Association

- Assam apex weavers & artisans cooperative federation

- Ahmedabad textile mills association

- The Rajasthan Textile Mills Association

- All india carpet manufacturers association

- Indian Jute Mills Association

- Spinners Association Gujarat

- Open End Spinning Mills Association

- Tamilnadu Spinning Mills Association

- Shingora Textiles Limited

- The Madhya Pradesh Textile Mills Association

- South Gujarat Textile Processors Association

- Indian Woollen Mills Federation

- Textile Machinery Manufacturers Association

- Association Of Synthetic Fibre Industry

- The Textile Association

- Garment Exporters Association Of Rajasthan (GEAR)

- All India Woollen & Textiles Association

- ASSOCIATION OF MAN-MADE FIBRE INDUSTRY OF INDIA (AMFII)

- Indian Textile Accessories And Machinery Manufacture Association

- MAHARASHTRA STATE TEXTILE HAND PROCESSORS ASSOCIATION

- The Clothing Manufacturers Association Of India

- Denim Manufacturers Association

- Eastern India Textile Mills Association

- Federation of Hosiery Manufacturers' Association of India

- Indian Sports Goods Industry's Manufacturer's and Exporters Association

- Federation of Indian Export Organisations

- Confederation of Indian Industry

- PHD Chamber of Commerce and Industry

- Northern India Textile Mills Association (NITMA)

- Knit Cloth Manufacturers Association

- South India Imported Machine Knitters Association

- Indian Jute Industries Research Association

- Jute Products Importers Association

- Computer Embroiderers Association

- Coimbatore Dist Powerloom Cloth Dealers Association

- The Federation of Tamilnadu Yarn Merchant's Association

- Coimbatore District Power-loom cloth Dealer Association

- South Indian Hosiery Manufactures Association

- Cotton Merchants Associaton

- Dyers Association Tirupur

- Tiruppur Export Knitwear Manufacturers Association

- Narrow Tape Manufacturers Association

- Tirupur Powerloom Association

- Screen Printer's Association of India

- Tirupur Steam Calendering Association

- Telangana State Federation Of Textile Association

- Andhra Pradesh Spinning Mills Association

- Garments Manufacturer & Wholesalers Association

- Andhra Pradesh Cotton Association

- Karnataka Hosiery and Garment Association

- The Ahmedabad Textile Processors' Association

- Coir Board of India

- Asha Handicrafts Association

- Basic Chemicals, Cosmetics & Dyes Export Promotion Council

- The Bombay Textile Research Association

- Khadi and Village Industries Commission

- Packaging Industry Association of India (PIAI)

- Jute Corporation of India

- West Bengal Hosiery Association

- Apparel Exporters Association of Ludhiana (APPEAL)

- Telangana and Andhra Composites Manufacturers Association

Snapshot

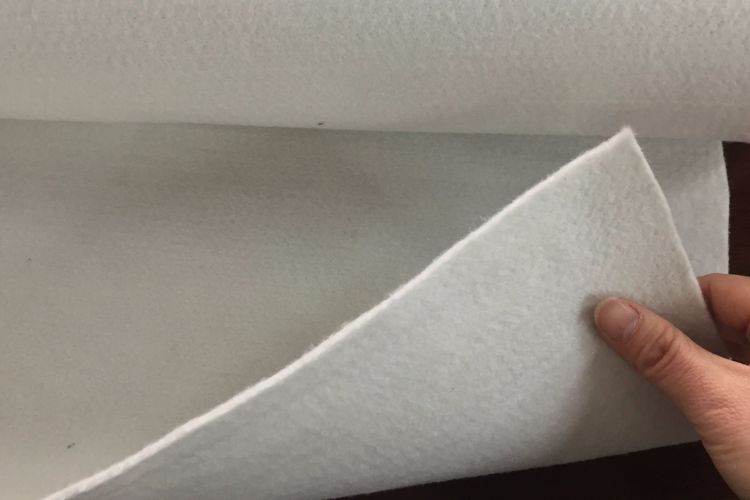

Needle Punch nonwoven fabrics are produced by barbed needles that interlock the fibers. This produces robust and thick fabrics without the use of chemical binders. In the Needle punching method, loose fiber webs are punched to produce robust fabrics that have good airflow and elasticity.

The basic materials used are natural fibers, synthetic fibers such as polyester and polypropylene, or a combination of both. This enables the production of versatile needle punch nonwoven fabrics. Being one of the leading producers of needle punch fabrics in India, the industry caters to various technical and industrial applications.

Needle Punch nonwovens have various applications in construction, filtration, automotive, and other sectors. Needle punched geotextiles and nonwoven geotextiles in India find applications in road construction, drainage, erosion protection, and soil stabilization. Nonwoven fabric for the automotive sector in India is applied for insulation, carpeting, trunk lining, and soundproof panels.

Types of Needle-punch fabrics are classified based on the type of fibers used, for example, nonwoven filter fabric used in India for air and liquid filtration, geotextiles for civil engineering applications, and industrial felts for padding, cushioning, and protective purposes.

-

xxx

asdasdasd

Modal Header

This is the text .

This is the text .

This is the text .

This is the text .